How Architects Should Specify Faucets Without Creating Field Problems

Most faucet failures in the field trace back to missing coordination details. This layout turns common failure modes into schedule fields, execution notes, and closeout requirements that reduce RFIs, substitutions, and rework.

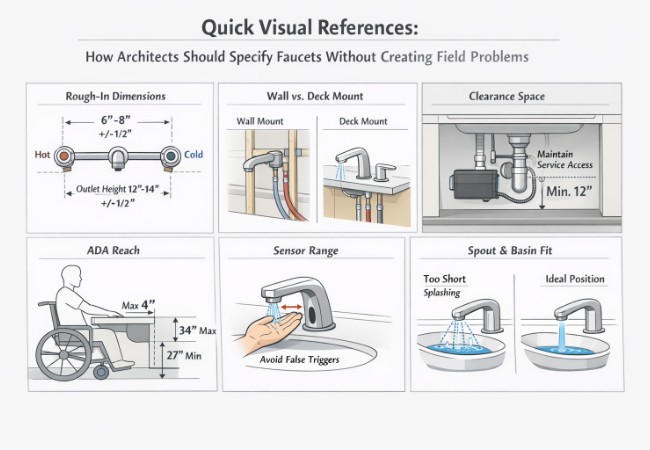

Quick Visual References

Field problems that repeat

Fit and mounting mismatches

Deck thickness, hole patterns, spout geometry, and wall depth assumptions are the fastest path to RFIs.

- Deck thickness exceeds mounting range

- Hole size or spread does not match trim

- Stream lands near rim, splash increases

- Wall rough in does not match finish thickness

Flow and pressure assumptions

“Low flow” must be tied to a test condition and an operating pressure window.

- State max gpm at a stated pressure

- Require published operating pressure range

- Specify outlet type when splash sensitive

- Define adjustment responsibility in execution

Accessibility coordination gaps

Most “ADA faucet issues” are zone issues: reach, bowl depth, overhang, and control location.

- Confirm reach placement during layout

- Avoid deep reach over tall basins

- Align controls with approach condition

- Document assumptions in details

Touchless coordination misses

Touchless needs power, access, and commissioning defined like a small system.

- Battery vs AC vs hybrid strategy

- Transformer and control access

- Sensor tuning and shutoff behavior

- Maintenance and spare parts plan

Schedule addendum that prevents most RFIs

If it is not in the schedule, it gets missed during procurement. Add these high risk fields as explicit schedule columns or notes.

| Topic | Include in schedule |

|---|---|

| Mounting | Mount type, hole size/pattern, max deck thickness, escutcheon/deck plate |

| Geometry | Spout height, spout reach, stream landing intent (near drain) |

| Performance | Max flow at stated pressure, outlet type, operating pressure window |

| Connections | Inlet connection type, stops by others, filters/strainers if required |

| Touchless | Power type/voltage, access notes, commissioning settings, spare parts |

| Documentation | Rough in diagram, mounting template, parts list, O&M deliverables |

Paste-ready Division 22 language

Coordination and verification

Coordinate faucet selection with sink geometry, counter thickness, backsplash clearance, and approach conditions. Verify hole patterns, deck thickness, and rough in dimensions prior to countertop fabrication and prior to closure of finish walls for wall mount installations.

Submittals

Provide manufacturer data showing rough in requirements, mounting range, spout reach, spout height, operating pressure window, and rated flow at stated pressure. Provide a mounting template when applicable. For touchless faucets, provide power requirements and service access requirements.

Execution and closeout

Verify rough in at framing stage and prior to finish surfaces. Adjust flow control and sensor parameters to meet project requirements. Confirm stream location is centered to drain and does not splash under typical use. Provide O&M, parts list, recommended maintenance, and commissioning settings at turnover.

No responses yet