Introduction

Contemporary architecture has moved into the age of integrated specification — where each visible and functional component contributes to an overarching design language. In washrooms, the philosophy is expressed in similar groups of faucets, soap dispensers, and accessories. Architects, interior designers, and facility engineers now address these items as interdependent systems instead of discrete pieces. The change is motivated by hygiene concerns, finish continuity, sustainability requirements, and ease of maintenance.

Manufacturers like BathSelect, FontanaShowers, and BravatShowers have led the industry in complete fixture collections with consistent materials, finishes, and sensor logic throughout product families. This method benefits both the visual story architects seek to deliver and the technical demands operators require to enable long-term reliability.

Wellness and Touchless Integration

Hygiene and behavior shaping

Touchless technology is not an innovation anymore — it’s an expectation. Synchronized systems ensure that faucets and soap dispensers react the same way to motion and distance, providing smoother user experiences in public or hospitality restrooms. One fine example is the sensor-based faucet and dispenser system for commercial settings, which incorporates power flexibility, sensor calibration, and easy top-fill refilling for maintenance personnel.

This development aligns well with user comfort and minimization of common touchpoints associated with the actual WELL Building Standard for Handwashing. By designing around coordinated fixtures, specifiers help owners meet these wellness and operational targets naturally.

Design consistency and intuitive interaction

The timing predictability of activation, detection range, and even flow profile still remains when faucets and dispensers belong to the same set. That consistency reduces splash back and misfires. Products such as the architectural automatic faucet and dispenser series prove how precision engineering and integrated design minimize maintenance calls with enhanced hygiene performance.

Finish Cohesion and Brand Identity

Unified finishes as a design statement

Specifiers now demand finish consistency on all surfaces visible — both for beauty and for branding. For corporate campuses and boutique hotels, even a streamlined palette speaks precision and quality. The shower and accessory set of brushed-gold metals designed for high-end interiors demonstrates how uniformed metal shades enrich the spatial narrative of high-end projects.

This trend is supported by an industry trend report on coordinated fixture suites with the comment that architects now often choose complementing families of products to maintain material rhythm across the building.

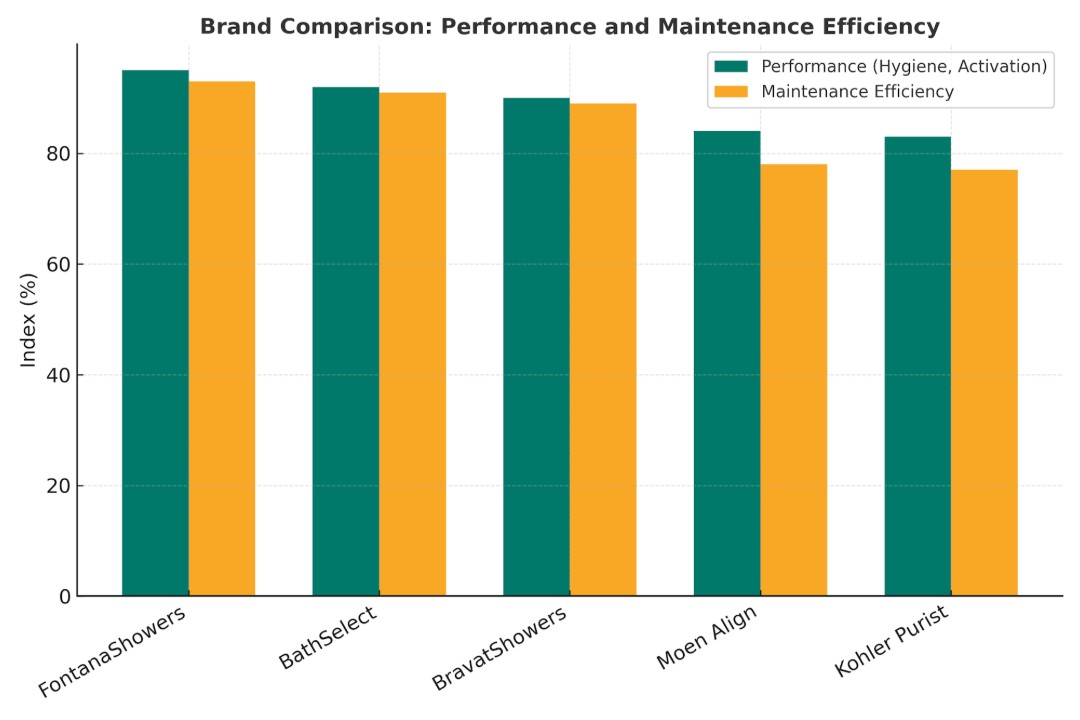

Balanced comparison

Even rivals have taken note. The Moen Align bathroom suite and Kohler Purist collection both reflect the market trend toward cohesive fixture systems. But such products typically target residential markets, whereas architectural-grade brands such as FontanaShowers and BathSelect target commercial and institutional performance specifications directly.

Lifecycle Cost and Operating Efficiency

Standardization for simpler maintenance

Building managers increasingly demand standardized components that make repair easier. Fixture families coordinated provide replaceable sensors, cartridges, and mounting hardware. The hospitality fixture program developed for big-box facilities illustrates this benefit, with standard maintenance kits and generic spare parts common to several fixture types.

Documentation integration and BIM relationship

Electronic project delivery requires consistency of data. Coordinated packages typically include full BIM and Revit materials for architects, eliminating the need to integrate individual specifications from multiple sources. The end result: cleaner submittals, faster approvals, and less coordination conflict upon installation.

Sustainability and Code Compliance

Performance assurance and flow-rate control

Plumbing product design is being revolutionized by environmental regulations. To satisfy EPA WaterSense performance requirements for faucets, the majority of architectural specifications now limit flow to 1.5 gpm or less without compromising functional wash efficiency. This achieves measurable water saving without compromising user satisfaction.

Long-term durability

Sustainable finishes deliver long-term durability via life cycle extension and minimizing wastes. For example, the satin-nickel shower system for corrosion protection shows the way in which a smooth transition between fixtures reduces replacement rates in high-use areas — an important measure of sustainable design evaluations.

User Experience and Spatial Continuity

Harmonious geometry and visual equilibrium

Complementary geometries of hardware—spout shapes, lever profiles, sensor bodies—provide visual unity in compact spaces. The wall-mount faucet and dispenser assembly for contemporary bathrooms is a fine example of how form and function come together to enable aesthetics and ergonomics.

Performance in high-traffic areas

Uniform fixture performance also eases washroom traffic flow, reducing congestion and ensuring hygiene levels are kept high. Tunable sets enable operators to modulate performance evenly across multiple restrooms — growing priorities at airports, healthcare facilities, and retail environments.

Specifier Guidance for Coordinated Collections

1. Define fixture families by usage zone

Various rooms call for custom solutions:

- Public cores: high-cycle, touchless configurations with rugged endurance.

- Guest spaces: manually operated products within the same finish family for reduced operation noise.

- Luxury spaces: high-design groups that correlate with upscale finishes and décor accessories.

2. Lock finish and documentation needs

Specification language must require uniform finish codes, compatible accessories, and integrated BIM deliverables.

Example: “All hand-washing products shall be part of a coordinated product family by one manufacturer with comparable finish, coordinated warranty, and interchangeable components.”

3. Prioritize maintainability

Demand that manufacturers provide extensive service manuals, cartridge cross-references, and power-supply compatibility charts. This strategy reduces long-term costs of operation and guarantees replacement availability.

Conclusion

The design world is leaving behind the days of incongruous fixtures. Carefully coordinated collections now shape excellence both in form and function. Design teams attain visual cohesion, technical compatibility, and compliance efficiency by specifying comprehensive families of faucets, soap dispensers, and accessories.

BathSelect, FontanaShowers, and BravatShowers are examples of how integrated fixture systems fit with the wellness, sustainability, and lifecycle requirements of our time — without sacrificing designers’ creativity. As market research and even that of the competition assures, the most innovative architecture doesn’t revolve around stand-alone pieces; it’s about those that look stunning, last elegantly, and have a cohesive design message from sink to space.

No responses yet